The first time I saw the lathe assembled, I was bemused. With the crotch wood on one side and the plank on the other, it comes across as quaint and impractical. On close examination, it is clear that this lathe saw years of serious use.

Of all the discoveries made during this research, the lathe might be one of the most exciting. At the Fisher house, there are several storage areas with unidentified objects. Early on, I spent considerable time sorting through all the objects but was unable to identify anything notable. After months of sorting through the archives, I opened one box that contained, among other things, a handful of old photographs of objects in the barn. There was a wheel that I recognized. Then the shingle horse. And then, there it was: I saw the lathe, standing assembled. My jaw dropped and my mind quickly sifted through the pieces in storage. Realizing I could locate every single component in that picture, I enlisted the help of another board director and we reassembled the lathe for first time in many years.

It is a strange thing.

Crotch wood is a foreign sight in most modern workshops but several surviving 18th- and 19th-century New England shop appliances suggest this practice was not unusual in Fisher’s time.

Crotch wood is a foreign sight in most modern workshops but several surviving 18th- and 19th-century New England shop appliances suggest this practice was not unusual in Fisher’s time.

One end of the lathe is made of a beech crotch slab, while the other is a single 2 3⁄4"-thick plank of birch or maple. The deliberate use of crotch wood is a clever technique that was used by many New England craftsmen. When Fisher needed an upright that had mass and two feet to stand on, it made perfect sense to use stock that already had those characteristics. Classifying this kind of rural ingenuity as naiveté is shortsighted because, from a performance standpoint, having continuous fibers running the entire length of the wood was a significant advantage. Every single component of the lathe retains numerous hewing and adze marks. The poppets are also irregular and appear to have been hewn to shape with an axe.

Some of these turning chisels were probably made by Blue Hill blacksmith Matthew Ray. This modest set was sufficient to take care of his furniture making needs.

Some of these turning chisels were probably made by Blue Hill blacksmith Matthew Ray. This modest set was sufficient to take care of his furniture making needs.

There are four poppets that survive, two of which fit this lathe. When both poppets are installed, as found in the archived photograph, there are two different center point heights. On the crotch end, there does not appear to be a way to connect a mandrel to a wheel. It is possible that the poppet on the crotch end was powered with a reciprocal spring pole. By tying a string onto a sapling mounted into the joists overhead, which then wraps around the workpiece and down to a treadle, the work is turned for cutting. Upon release of the treadle, the sapling, in tension, pulls the treadle back for another turn. The middle poppet arrangement on the lathe allowed Fisher to use a treadle to turn a large wheel mounted overhead. As Fisher pumped the treadle connected to the wheel’s crankshaft, the wheel turned, transferring the rotation to a mandrel on the poppet with a belt.”

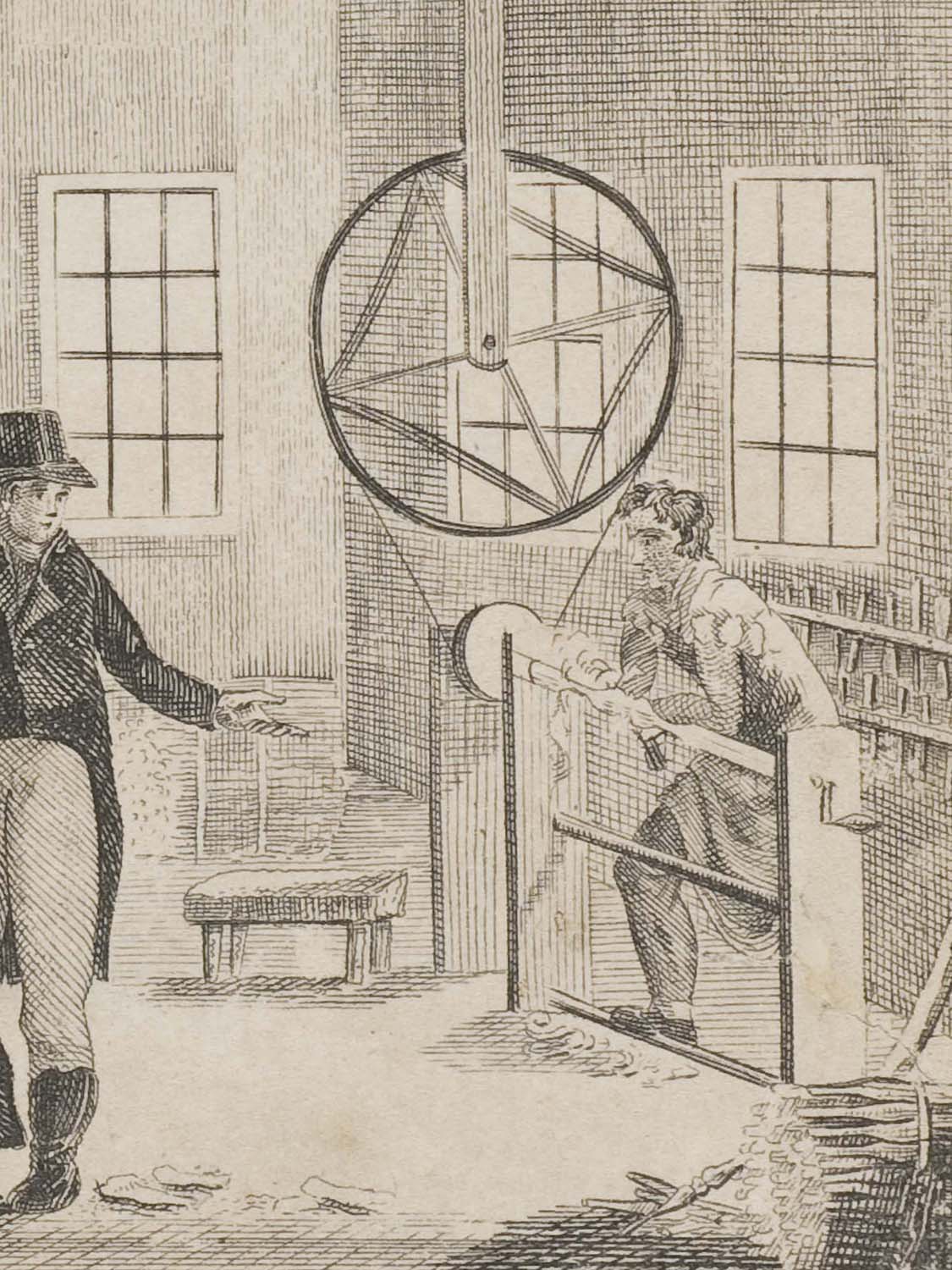

This detail from the 1813-1814 tradecard of the William Buttre Chair Manufactory shows a turner using a lathe with a wheel swung overhead, just as Fisher described in his journals. – COURTESY, THE WINTERTHUR LIBRARY: JOSEPH DOWNS COLLECTION OF MANUSCRIPTS AND PRINTED EPHEMERA.

This detail from the 1813-1814 tradecard of the William Buttre Chair Manufactory shows a turner using a lathe with a wheel swung overhead, just as Fisher described in his journals. – COURTESY, THE WINTERTHUR LIBRARY: JOSEPH DOWNS COLLECTION OF MANUSCRIPTS AND PRINTED EPHEMERA.

– Joshua A. Klein, excerpt from Hands Employed Aright: The Furniture Making of Jonathan Fisher (1768-1847)